Installation

General Requirements

Random Length Continuous (RLC) is the most common method of applying Lock-Deck. It allows the use of mixed lengths of material on a variety of span conditions, providing high structural efficiency and an attractive appearance.

Installation Instructions

The allowable RLC roof loads recommended in the span table are based on actual full-scale tests, where the decking was laid in conformance with specific rules. Install as follows for equivalent performance.

- The deck must be continuous over three or more spans of approximately equal length, with each piece of deck over at least one support. Other situations require special design.

- Place decking to disperse end-joints as randomly as possible.

- The distance between end-joints in adjacent rows of decking is at least two feet.

- The distance between end-joints in rows of decking separated by only one row is at least one foot.

- End spans shall be carefully planned and placed. To ensure that end spans perform as indicated by the span table, follow one of these practices:

- Eliminate end-joints in one-third of the decking courses, or

- Provide a cantilevered overhang, free of end-joints, equal to 20% of the end span, or

- Shorten the end span by 10%

Where one of these practices cannot be applied, end span deflection may exceed the values shown. Construction practice generally accepts the 10% reduction in second spans.

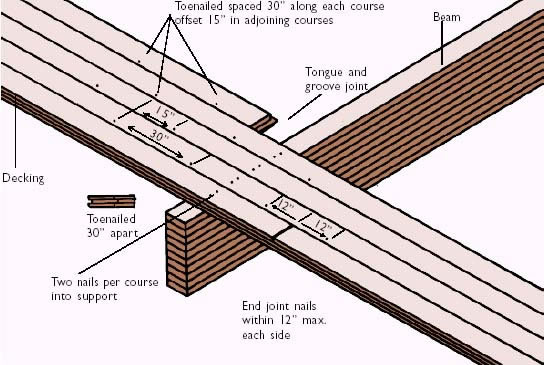

- Decking should be end-matched and toenailed within one foot of all ends (see Attachment Procedures below).

Diaphragm Construction

Lock-Deck can be engineered to carry diaphragm shear forces from earthquake and high-wind forces.

The most used method for obtaining diaphragm resistance is to install plywood or OSB over the Lock-Deck. The nailing of panel edges is the same as for panels installed over joists. The Lock-Deck provides the required blocking.

Lock-Deck laminated roof or floor decking in 3 in., 4 in., and 5 in. thicknesses may be designed to resist lateral forces when a 3/8 in. bead of 3M adhesive No. 5200 is applied on top of the tongue-and-groove joint between adjacent decking courses. Randomly applied decking may be used, and the nailing schedule is the same as regular deck.

Either diaphragm design must have a continuous chord along all sides to resist the moment forces.

Nailing Schedule

Toenailing along courses:

- 6d@30 in. o.c. for 2 in. nominal

- 8d@30 in. o.c. for 3 in. nominal

- 16d@30 in. o.c. for 4 in. nominal

- 16d@30 in. o.c. for 5 in. nominal

Face nailing to supports:

- 16d for 2 in. nominal

- 20d for 3 in. nominal

- 30d for 4 in. nominal

- 50d for 5 in. nominal

Screws

Screws can be used as an alternate, providing equal shear and withdrawal resistance are provided.

Attachment Procedures

Contact us to discuss your project with a laminated decking expert.